Services

Services

Our comprehensive range of service and support options serve production and R&D customers around the world, to include those within the private sector, government, and universities.

Alliance MOCVD services include:

- Technical phone support.

- On-site service as needed.

- MOCVD service and maintenance contracts.

- Installation and Demonstration services.

- MOCVD system decommission and moving services.

- Refurbished, upgraded, and custom MOCVD systems.

- Facility, tool, and process audits.

- Process development.

The benefits of Alliance MOCVD service and support

Minimizes production costs.

Increases productivity.

Improves device quality.

Improves delivery-time performance.

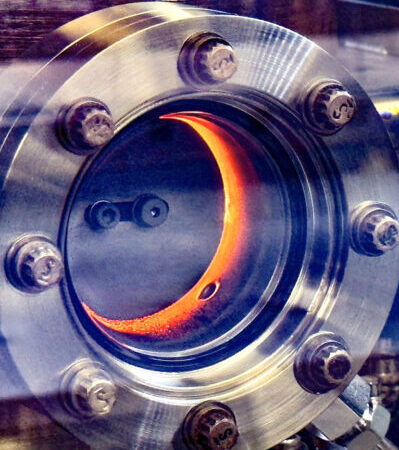

Preventative Maintenance

Maintenance, in the form of cleanings, worn part replacement, and alignments, is necessary to keep tools running at their peak performance levels.

Effectively scheduling tool maintenance, tracking part lead times, being aware of technician knowledge and skill levels, and implementing proper safety protocols, are all critical components of performing a proper PM.

Before

After

MOCVD preventative maintenance plans cover

- Small or large production and R&D tools.

- Annual, semi-annual, and/or quarterly service.

- Inventory of key spare parts on hand.

- Change of particle filter (quarterly).

- Cleaning of chamber (quarterly).

- Disassembly, cleaning, and reassembly of chamber & exhaust (annual).

- Replacement of exhaust seals (annual).

Benefit of performing regular maintenance

- Reduces/eliminates unscheduled downtime.

- Keeps system operating more efficiently.

- Improved operating efficiency impacts quarterly operating expenses.

- Greater operating efficiency in a power and resource intensive industry directly impacts operating costs and the bottom line.

Tool Support

Properly decommissioning and moving a tool is challenging and labor intensive. Our engineers have the training and experience to ensure the decommissioning, crating and moving, and the final installation at its new destination are completed properly and safely.

MOCVD tool support

- Domestic and international moves.

- Installation and demo.

- Decommission services.

- MOCVD tool crating and moving services.

Relocate with ease. We ensure that your system is properly packed and safe for transportation.

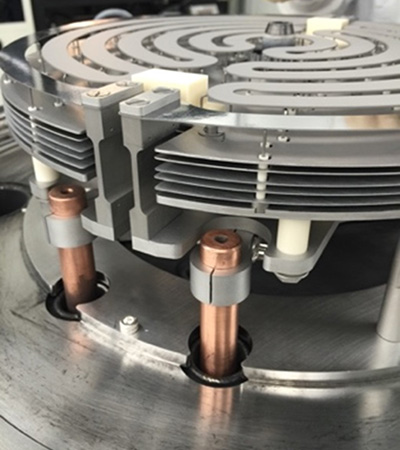

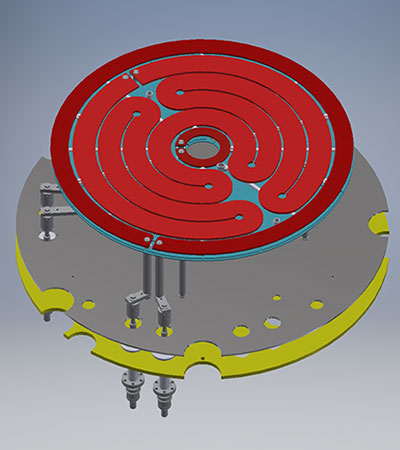

Engineering Custom Tool Design

Our skilled CAD engineers can design and manufacture a custom research or production tool, large or small, to meet your specific requirements.

- Complete custom tool design and manufacture to meet your specifications.

- Custom tool modification to accommodate desired change in process.

Service & Repair

We understand that every second your tool is down, that impacts your bottom line. At Alliance MOCVD we always have an engineer on the other end of the line, ready to take the time to understand your needs, and prepared to get you up and running again as quickly as possible. Our field service engineers’ advanced troubleshooting skills and experience allow for quick repairs when unexpected downtime does occur.

Alliance MOCVD Service offering:

- Technical phone support.

- On-site service, as needed.

- Preventative maintenance.

- Emergency on-site service.

- Service Contracts.

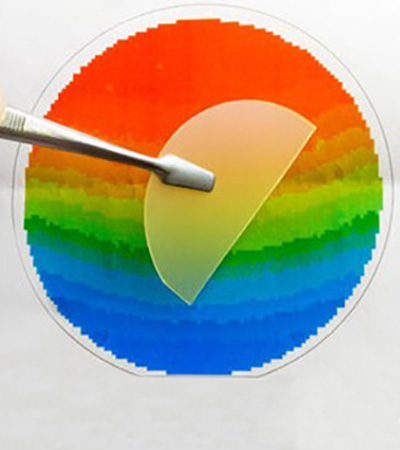

Turnkey Systems & Solutions

Interested in finding out more about our turnkey solutions and competitive pricing?

How can we help advance your next big discovery?

Our highly-qualified teams are on the frontlines with our customers, resolving process and hardware issues and developing recipes, to help you solve your tough research challenges.

How can we help you today?

US / English

US / English